Calcular emisiones de CO2

| CO2 SAVER BY USING POST-TENSIONING |

|||

|---|---|---|---|

| 1. MATERIALS SPECIFICATION | |||

| Concrete strength_28 days fck/fck,cube (Mpa) | |||

| Fluency strength rebars fyk | |||

| 2. BUILDING DATA | |||

| SELECT USE FOR THE SLABS: | |||

| DL: (SUPERIMPOSSED DEAD LOAD): | |||

| LL: (LIVE LOAD- USE): | |||

| Total area of slab (m2) |

|

||

| Number of storeys: |

|

||

| Height of storey: (m) |

|

||

| Total height of building = PT | |||

| Total height of building = HA | |||

| 3.DATA OF THE PANEL | |||

|

|||

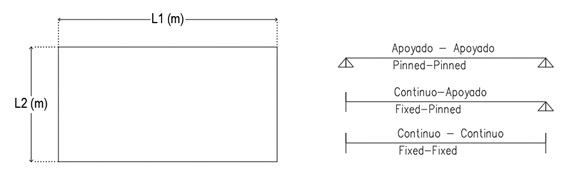

| Larger Length (m) = L1 |

|

||

| Span's restraint condition L1 | |||

| Shorter Length (m) = L2 |

|

||

| Span's resgtraint condition L2 | |||

| 4.SELECTION OF TYPE OF SLAB | |||

|

|||

| DIRECTION OF THE SLAB: | |||

| TYPE OF SLAB: SOLID SLAB |

LOSA_MACIZA_SOLID_SLAB |

||

| SLAB CONFIGURATION: | |||

| PRESENCE OF BEAM: |

|

||

| 5.SECTION DESIGN POST-TENSIONING SLAB | |||

| RECOMENDED THICKNESS (Post-tensioning)= |

|

||

| SELECT SECTION FOR DESIGN (POST-TENSIONING SLAB) |

MACIZA-SOLID SLAB |

||

| Self weight's slab: |

|

||

| Minimum density's tendon = kg/m2 |

|

||

| Maximum density's tendon = kg/m2 |

|

||

| % SELF WEIGHT TO BALANCE (between 40 to 70%) |

|

||

| SELECT DIAMETER OF THE STRAND | |||

| Prestressed steel required mm2/m2 to balance self weight |

|

||

| Number of strands per m2 or number of strands per ribs |

|

||

| Density of prestressed steel |

|

||

| Verification of minimum pre compression |

|

||

| Minimum rebar steel (geometrical ratio) |

|

||

| 6.SELECTION DESIGN CONCRETE REINFORCEMENT SLAB | |||

| RECOMMENDED THICKNESS (Concrete reinforcement) |

|

||

| Required thickness by strength (mm) |

|

||

| REQUIRED SECTIONS'S DESIGN |

|

||

| SELECT THICKNESS (R.C.) (introduce the figure closest to RECOMMENDED THICKNESS) | |||

| Self weight's slab: |

|

||

| 7. CALCULATE EMISSIONS CO2 / SLAB | |||

| Post-tensioning Condition Material Relation | |||

| Volumen of concrete: |

|

||

| Rebars reinforcement (span) |

|

||

| Rebars reinforcement (supports) |

|

||

| Prestresing steel |

|

||

| Injection volumen: |

|

||

| Ducts: |

|

||

| Reinforcement Concrete Condition Material Relation | |||

| Volumen of concrete: |

|

||

| Rebars reinforcement (span) |

|

||

| Rebars reinforcement (supports) |

|

||

| Post-tensioning Condition CO2 kgm2 emission | |||

| Volumen of concrete: |

|

||

| Rebars reinforcement (span) |

|

||

| Rebars reinforcement (supports) |

|

||

| Prestresing steel |

|

||

| Injection volumen: |

|

||

| Ducts: |

|

||

| TOTAL C02 Kg/m2 (PT) |

|

||

| Reinforcement Concrete CO2 kg/m2 emission | |||

| Volumen of concrete: |

|

||

| Rebars reinforcement (span) |

|

||

| Rebars reinforcement (supports) |

|

||

| TOTAL C02 Kg/m2 (RC) |

|

||

| 8. TOTAL EMISSIONS CO2 / SLAB | |||

| CO2 EMISSIONS IF YOU USE POST-TENSIONING TECHNOLOGY |

|

||

| CO2 EMISSIONS IF YOU USE REINFORCE CONCRETE (non use of post-tensioning) |

|

||

| REDUCTION OF EMISSION USING POST-TENSIONING |

|

||

| PERCENTAGE OF REDUCTION OF CO2 EMISSIONS |

|

||

|

|||